The Process

Before the construction of the sugarhouse, maple syrup production took place in the woods or the farmyard, with syrup being boiled in an open pan. After the initial boiling, the syrup was taken to the family kitchen to be finished to the correct consistency. We’ve kept true to this historic process as much as possible but within the walls of our brand new sugarhouse. This results in a limited edition small-batch syrup that has perfect flavor and consistency.

Tree Selection and Tapping

Trees are selected long before the sugaring season begins. Slippery Slope Maple operates a gravity-fed sap collection system so the location of trees on the slope is crucial for optimum sap flow. Once trees are chosen in winter, lines are run and everything is set up for when the magic happens- the tapping of the trees and the first sap runs.

Sap Collection

Our sap collection begins as soon as the daytime temperatures start rising above freezing while the night temperatures stay cold. Sap flow is an interesting process as it is influenced by both temperature and sunlight. Warmer sunny days followed by cooler nights create a pressure difference that promotes sap flow. Timing the tapping of trees is also important because after about three or four weeks, the tap holes start to close and the sap stops flowing.

Nature decides when the sap will flow... we decide when the time is right to tap!

Boiling and Evaporation

The collected sap ends up in a stainless steel collection tank. We use a wood-fired evaporator fueled by logs carefully selected from our property. As a result, we’ve created a self-sufficient system from start to finish. From the time our sap is first heated in our evaporator it only comes in contact with stainless steel equipment. While it is considered safe to put hot sap into plastic containers, we just don’t like the idea of it. We keep everything stainless and package our syrup directly into glass or metal containers.

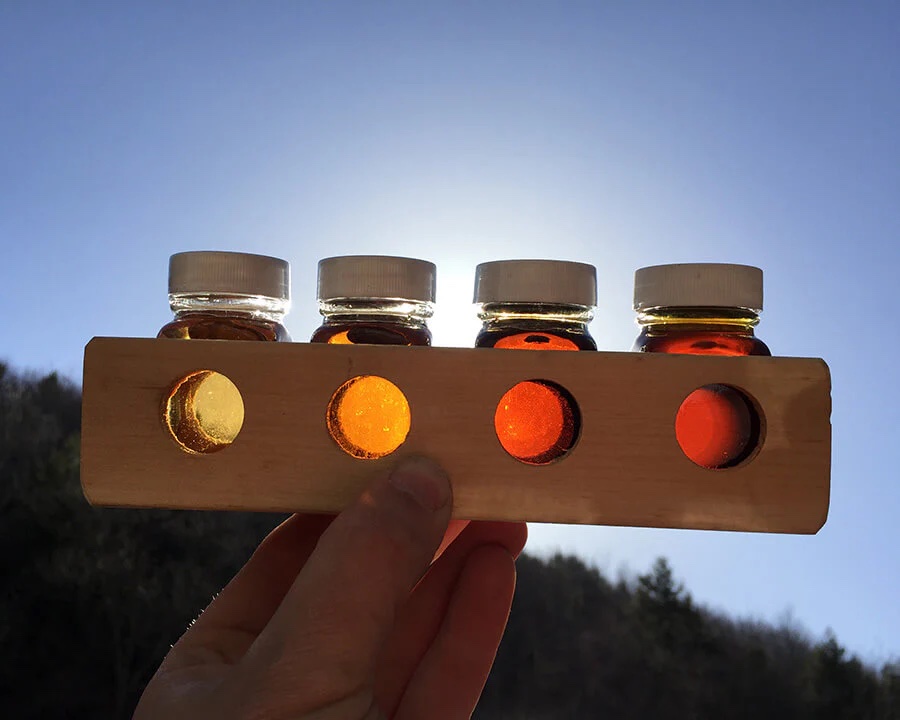

Filtering and Packaging

We made the decision not to use reverse osmosis to extract water from the sap prior to boiling as we feel the extra time the sap spends over the wood fire adds to the flavor. Is this an economical decision? Heck no. None of the larger producers could ever do it this way because reverse osmosis is key to cutting down boiling time. But, since we are a small producer, we’ve chosen to keep doing things the old fashioned way. It takes more time but the end result is worth it!